Vehicle Engineering

Strengthening and accelerating vehicle development

by combining conventional methods and innovative technologies

It is required to utilize new advanced technologies (for example, AI, advanced CAD and CAE, efficient meshing, virtual simulation, materual and measurement technoligy and rapid prototyoe) in the basic design process such as concept validation, CAD detailed deaign, CAE, prototype, testing and validation for homologation and the entire VAVE.

We will support the customer to win the race to develop a vehicle in a realtime global scale from inidividual component to an entire vehicle.

Trends

Trend

1Efficiency of Developement

Shorten product development lead time through the latest and advanced development methods such as virtual simulation etc.

Trend

2Cost Reduction

Reduction of development costs and workload through VA/VE and suuply chain analysis.

Trend

3Advanced Technology

Update and accumulate of knowledge on advanced technologies that follows complex requirement definition and clarification

Trend

4Breakthrough of Resource Shortage

Collaborate with proven engineering partners to optimize development resources and accelerate development on a global scale

Features of SCTM Engineering

Understanding of development processes

We can support the customer with a wide range of services and best practices based on our experience and understanding of the entire development process from concept design to mass production set up, as well as understanding of the requirements and various design standards of each global client.

Team of advanced

engineers and

bilingual experts

SCTM engineering’s bilingual experts, who are well familiar with the automotive industry, serve as a single point of contact to execute offshore development. Therefore, we will lower the hurdles of outsourcing including offshore and also support the optimization of the customer's development workloads.

The latest technologies

and global ecosystems

Our experience in virtual engineering and simulations such as model-based development, know-how such as AI-based automation and collaboration with the global ecosystem will enable acceleration of the development and support for complex requirements.

Service Offerings

Concept Validation

Through market research, target setting by benchmarking, design cencept and styling plan validation, we support the strategic planning of customer's product to be designed and developed.

Design

In addition to basic design of varieties of products such as interior parts, exterior parts, body parts, chassis and drivetrains etc., we also provide design reviews and feedback to ensure the design quality.

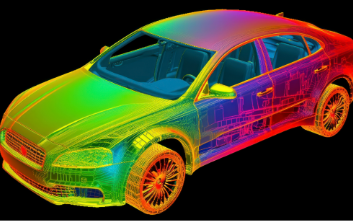

CAE

We support from meshing work to analysis and evaluation related to durability and reliability by structural analysis, mechanical analysis, thermo-fluid analysis, electromagnetic field analysis, vibration analysis etc. in a virtual environment with efficient feedback.

Prototype

We create an initial experimental model based on the assumption of transition to a mass production model, and support acceleration of preparation for testing, feedback to design development and collaboration.

Testing and Verification

We support test verification of designed models in a virtual environment such as model-based development (MBD), as well as test verification using physical experimental models.

VA/VE

Through analysis and benchmarking of materials and development processes, we support our customers to generate ideas of cost reduction in the development process and to execute these ideas in the actual design development.

Solution

Contact

Please contact us or download documents to know more about us below.